Self Care / Cosmetic / Pharma

Cosmetic/Self Care

Lasting Impact in Cosmetic Labeling

Cosmetic products are one of the most powerful communication tools that directly reflect a brand’s aesthetic vision and perception of quality. Whether applied to bottles, tubes, jars, or compact packaging, label solutions that fit the surface perfectly, maintain their form, and preserve their appearance even after prolonged use help strengthen your product’s presence on the shelf.

Premium Appearance, Durable Performance

Our label materials, specially developed for cosmetic packaging of varying shapes and sizes, provide brands with an elegant look through clear, metallized, and textured surface options. Thanks to their resistance to moisture, oils, and frequent handling, the labels do not peel, fade, or lose their form.

Pharma

Safe Formulations and Low-Migration Properties

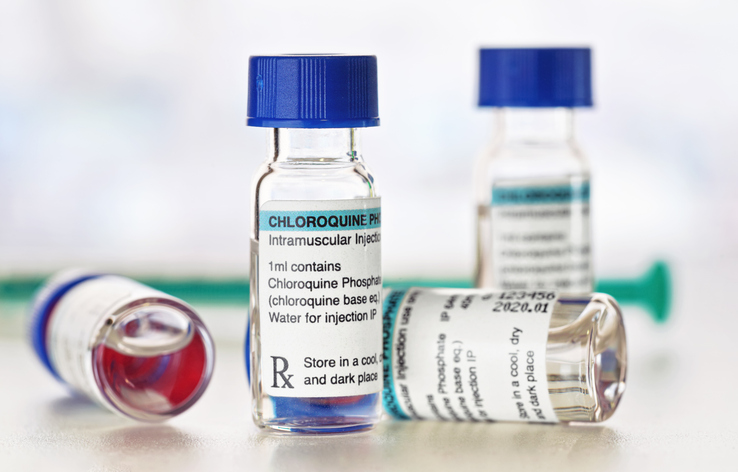

Labels used in pharmaceutical and healthcare products are not merely decorative elements; they are essential components for product safety, traceability, and regulatory compliance. For this reason, the chosen label material must be fully compatible with both the product’s life cycle and the environmental conditions it will encounter.

Labels applied to pharmaceutical packaging must not pose any risk of migration—meaning no transfer of substances from the label into the product. Low-migration adhesives and facestock materials specifically designed for this purpose help maintain chemical stability and provide high safety, particularly for oral medications, pediatric products, ampules, and inhalation devices.

Materials Designed for Demanding Conditions

Since some pharmaceuticals are stored in cold-chain environments, others in heated conditions, and many undergo rigorous sterilization processes, the labels applied to these packages must maintain consistent performance under challenges such as condensation, UV exposure, sterilization steam, abrasion, and chemical contact. In applications like sample tubes, serum bottles, and syringes used in hospitals and laboratories, strong adhesion and print integrity are especially critical to ensure that information remains secure and legible throughout the product’s use.

Key Considerations for Successful Labeling on Pharmaceutical Bottles

Choosing the right label material is essential to ensure that pharmaceutical products remain safe, traceable, and readable throughout their entire lifecycle. The first step is identifying the correct packaging surface—glass, plastic, or metal—each requiring specific adhesion properties. Additionally, the environmental conditions the product will face, such as cold-chain storage, temperature fluctuations, sterilization processes, abrasion during transport, or chemical exposure, have a direct impact on label performance.

The printing method is another critical factor. Selecting surface coatings compatible with thermal transfer, laser, inkjet, or variable-data printing ensures that all information stays clear and durable. Moreover, security features used to prevent counterfeiting—such as holograms, specialty inks, or tamper-evident constructions—play an important role in pharmaceutical labeling.

For these reasons, choosing label materials specifically engineered for the pharmaceutical and healthcare sector is the most reliable way to maintain product safety, meet regulatory requirements, and ensure continuous traceability throughout the supply chain.